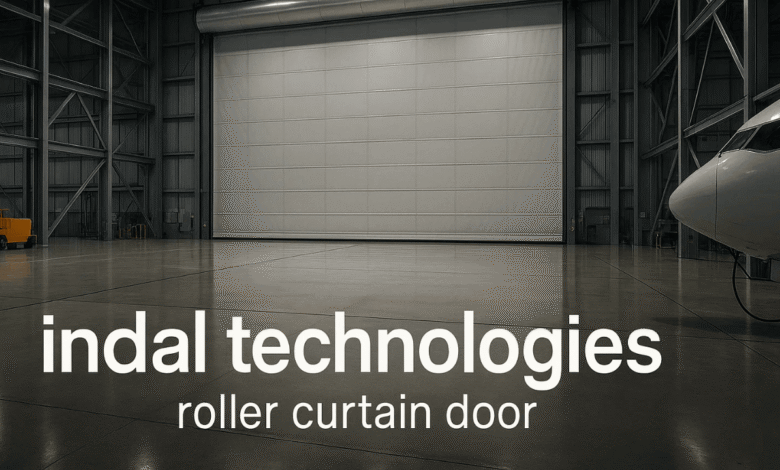

Having a reliable and large-scale access system is essential for facilities such as aviation hangars, naval docks, manufacturing plants, and large logistic centers. The indal technologies roller curtain door is designed for such heavy-duty environments, offering durability, space efficiency, strength, safety functions, and long-term performance. This guide explains how the system works, where it is commonly installed, and what makes it a preferred option for demanding operations.

The indal technologies roller curtain door stands apart from traditional doors because of its curtain-based structure, motor-operated lifting mechanism, structural durability, and ability to handle extremely wide openings. Instead of rigid metal panels, the door uses a reinforced curtain material that rolls into a compact barrel located above the door frame, saving both structural load and usable space.

What Defines the indal technologies roller curtain door

The indal technologies roller curtain door is an engineered access system using a strong, flexible curtain instead of segmented panels. This design enables the door to span oversized openings efficiently. Its construction typically includes:

- curtain sheets made from industrial fabrics

- reinforced stiffeners

- motorized lift system

- side-guide support channels

- automatic safety components

Because of its scalable construction, the door is widely applied in environments where large vehicles, aircraft, machines, or vessels must move quickly and safely.

How the indal technologies roller curtain door Operates

The indal technologies roller curtain door functions using an automated drive system positioned at the upper housing of the door. The motor winds the curtain upward into a cylindrical drum, eliminating sideways tracking or heavy vertical stacking. The curtain lowers smoothly using tension-controlled motion, ensuring stability even under wind or mechanical pressure.

Key internal elements often include:

- heavy-torque motor system

- reinforced winding barrel

- load-balanced rollback mechanism

- sealed utility compartments

- safety override release

This design ensures silent functioning and smooth speed transition during both upward and downward movement.

Features That Make indal technologies roller curtain door Stand Out

Several notable features distinguish the indal technologies roller curtain door from other types of industrial doors:

- compact operating footprint

- long-span sealing capability

- high resistance to environmental exposure

- compatibility with access automation systems

- adaptability to custom widths

For facilities running continuous operations, this door style increases mobility, reduces downtime, and maintains controlled indoor conditions.

Common Installations of indal technologies roller curtain door

Industrial sites that regularly require large-opening systems often choose this design. The most common locations include:

Aviation hangars

Aircraft maintenance areas need broad openings and fast opening cycles. A roller curtain design minimizes structural load while maintaining secure indoor containment.

Shipyards and maritime structures

Docking areas and assembly bays often require open access for ship hulls, large vertical structures, and equipment transport.

Heavy manufacturing plants

Facilities with large-scale machinery benefit from wide uninterrupted openings, easy forklift movement, and reduced restriction points.

Defense-controlled zones

Explosive-controlled and protected areas need controlled access. The structure can be reinforced depending on project needs.

Bulk storage and logistics warehouses

Where ongoing vehicle entry exists, the system improves movement and maintains environmental integrity.

Benefits of Selecting indal technologies roller curtain door

Choosing a system like the indal technologies roller curtain door gives industrial facilities measurable advantages such as:

- reduced maintenance on structural systems

- improved traffic throughput

- reduced space obstruction

- increased safety margins in high-risk sites

- controlled wind and weather influence

Additionally, installations often produce energy savings due to minimized uncontrolled airflow.

Installation and Technical Integration

Installation begins with mechanical measurement, frame alignment, and mounting of guide rails. Once reinforced anchoring is installed, the curtain housing is attached, followed by:

- motor and gearbox alignment

- barrel-mounted curtain assembly

- lateral guide attachment

- roller tension adjustment

- calibration of movement cycles

After mechanical setup, electrical systems and emergency override switches are activated. Testing cycles ensure synchronized motion and safety functionality.

Maintenance Recommendations for indal technologies roller curtain door

Maintaining reliability means regularly checking:

- operating speed consistency

- curtain smoothness with no fold deterioration

- lubrication of main drive units

- tension adjustments in winding assemblies

- response time of emergency stop controls

Scheduled inspections maintain consistent function while reducing operational downtime.

Why Industries Continue Using indal technologies roller curtain door

Compared to traditional steel shutters or panel-built sectional doors, the indal technologies roller curtain door offers greater flexibility, reduced structural load, and faster controlled access. It is also adaptable in shape and size, allowing custom-fitted solutions regardless of height or span.

Facility operators value this system because it increases workflow efficiency, supports heavy equipment movement, and reduces structural obligations when designing or extending buildings.

Considerations Before Installation

Before installing an indal technologies roller curtain door, companies should evaluate:

- environment exposure levels

- clearance requirements near support beams

- operational frequency

- remote access preferences

- emergency use design

Some locations may also opt for insulation-enhanced materials to improve indoor stabilization.

Why the indal technologies roller curtain door Represents Modern Industrial Design

Modern industrial development is shifting toward optimized spatial design, safety compliance, and automated systems. The indal technologies roller curtain door reflects this trend by combining controlled movement, strong reinforcement capability, electrical automation, and large-scale accessibility in a single solution.

Its curtain-based construction makes it adaptable to both new structural layouts and existing facility upgrades.

Conclusion

The indal technologies roller curtain door is a reliable access system for large-scale facilities requiring clean operation, safety compliance, oversized opening capacity, and fast movement. Its curtain-based design and structural adaptability make it a strong choice for aviation hangars, shipyards, warehouses, and heavy-industrial complexes. With appropriate installation and routine servicing, the system can operate for years under demanding conditions, increasing operational convenience and optimizing facility workflow.

FAQs

What makes indal technologies roller curtain door different from standard gates?

It uses a specially reinforced curtain that rolls vertically, allowing wide openings with maximum space advantage.

Can the door support outdoor-facing structures?

Yes, the curtain material and side support frames can withstand wind, weather, and external exposure.

Is manual operation possible during emergencies?

Most setups allow manual override through controlled release systems.

Does the system support automation and sensors?

Yes, it typically integrates signal sensors, stop functions, controls, and programmable access settings.

What environments most benefit from this system?

Hangars, shipyards, warehouses, production units, and defense locations where very large access pathways are required.